Joint Factory Fire Drill with Tainan Fire Department Strengthening Multi-Agency Collaboration for Enhanced Chemical Hazard Response

2025/09/18 SKPShih-Kuen Plastics Cross-Agency Collaboration Enhances Emergency Response Capabilities.

Shih-Kuen Plastics partnered with Tainan City Fire Bureau's Second Rescue Brigade on September 18, 2025, to conduct a comprehensive factory fire drill at our Ma-Dou plants. The exercise brought together firefighters, our in-house emergency response team, Tainan Environmental Protection Bureau, and the Environmental Incident Response Team to establish effective cross-agency coordination mechanisms and strengthen chemical disaster response capabilities.

Advanced Equipment and Tactical Deployment

The drill, led by the Tainan Fire Department, showcased several cutting-edge firefighting technologies and tactical innovations:

Advanced Fire Suppression Systems

- Water Mist Fire Engine (Unit 17): Provided superior cooling and smoke suppression, enabling closer approach to fire sources with enhanced safety.

- H-Card (Hazard Identification Card): Utilized facility chemical inventory and floor plans to establish cold, warm, and hot zones, supporting command decision-making in real-time.

- Fire Scene Rescue Mask Packages: Improved oxygen supply for personnel operating in hazardous environments.

- Search Rope Lights and Position Markers: Enhanced search efficiency and personnel tracking during rescue operations.

- Firefighting Robot: Deployed for reconnaissance and standoff operations in high-risk zones, minimizing personnel exposure to hazardous conditions.

- Chemical Decontamination Tent: Ensured thorough chemical residue removal from personnel, preventing secondary contamination.

Commitment to Corporate Fire Safety Excellence

Shih-Kuen Plastics maintains a long-standing commitment to supporting local disaster prevention and response capabilities. We continuously refine our in-house emergency response team training and enhance our facility hazard information systems.

During the drill, our team coordinated closely with fire department personnel, utilizing H-Card protocols to establish on-site hazard identification and zone classification. Designated personnel provided real-time access to chemical inventories and facility layout diagrams, enabling rapid assessment and tactical deployment by fire crews.

As part of our ongoing commitment to public safety and community welfare, Shih-Kuen Plastics donated our 6th ambulance in 2025. We remain dedicated to regular participation in emergency drills and tactical discussions, continuously improving disaster resilience in high-risk industrial environments.

Building Community Safety Through Partnership

Our Three-Pillar Safety Commitment

Shih-Kuen Plastics upholds our "Triple Safety Commitment" — Employee Safety, Environmental Safety, and Community Safety — as fundamental operational principles. This joint exercise reinforces our corporate disaster preparedness and resilience. We commit to continuous improvement across three key dimensions:

1. Information Transparency and Real-Time Support Proactively provide chemical inventories and facility layout diagrams to fire departments, ensuring timely and complete information disclosure to support emergency command decision-making.

2. Training Enhancement and Process Refinement Strengthen in-house emergency response teams and cross-agency collaboration training through regular drills and continuous review, refining emergency response standard operating procedures.

3. Management Systems and Continuous Improvement Leverage our ISO 14001 Environmental Management System foundation to drive daily safety improvements, deepening environmental and safety management practices to protect employees and surrounding communities.

Looking Ahead

Shih-Kuen Plastics will continue to maintain close collaboration with local fire departments, fulfilling our corporate social responsibility and working together to build a safer, more resilient community.

About Shih-Kuen Plastics

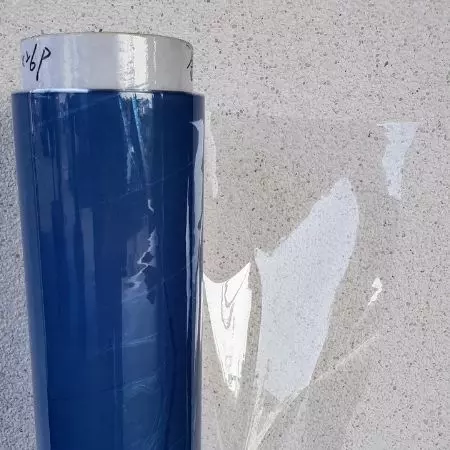

Established in 1986, Shih-Kuen Plastics specializes in flexible PVC sheet manufacturing with 39 years of expertise. ISO 9001 and TÜV certified, we serve customers across 50+ countries while maintaining strong commitments to employee safety, environmental protection, and community welfare.